The gas production principle of the RX gas generator is to mix natural gas and air in a certain proportion, and then prepare RX gas through an externally heated reaction tank equipped with a catalyst.

The gas production process of the RX gas generator involves mixing natural gas and air in precise proportions, followed by the production of RX gas in a heated reaction tank equipped with a catalyst. This reaction occurs externally to generate RX gas. The primary components of the RX gas, after the raw gas is mixed, cracked, cooled, and undergoes other processes, include CO, H₂, N₂, as well as trace amounts of H₂O, CO₂, CH₄, O₂, and other gases.

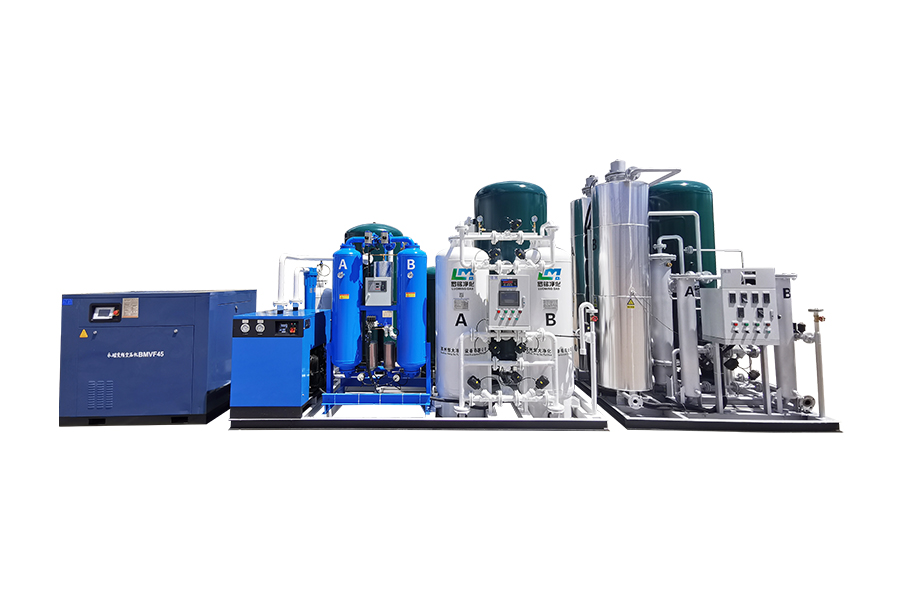

The RX gas generator structure of Jiangsu Luoming consists of several key parts:

1. Raw Gas Supply and Mixing System: Ensures accurate blending of natural gas and air in the required ratio.

2. Cracking Device: Facilitates the thermal cracking process to break down the raw gas into its desired components.

3. Product Gas Cooling Device: Cools the product gas after cracking to ensure stable output.

4. RX Gas Output System: Delivers the generated RX gas to the required output points.

5. Detection Instruments: Monitors and measures the quality and composition of the generated gas.

6. Control System: Manages and regulates the entire gas generation process for optimal performance.

English

English русский

русский Français

Français Español

Español عربى

عربى