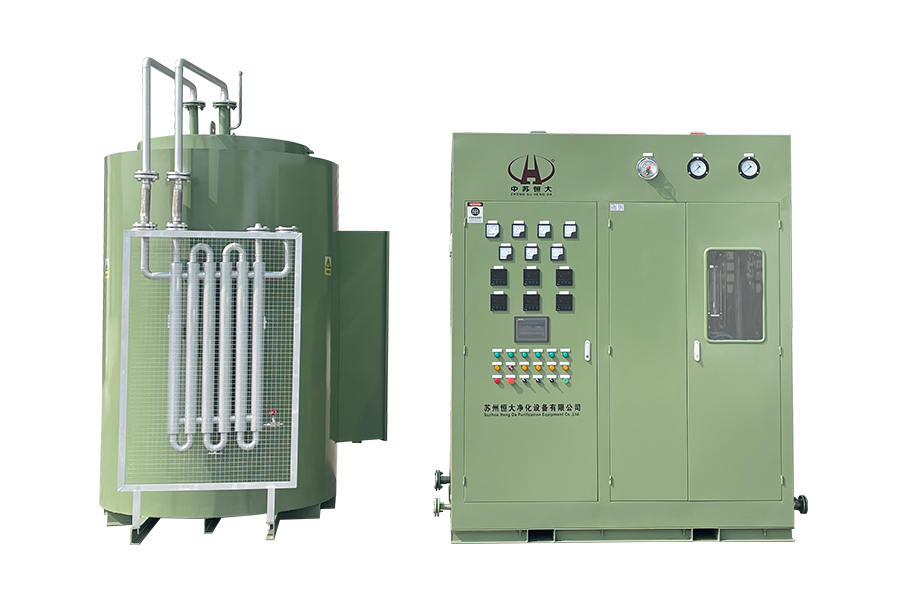

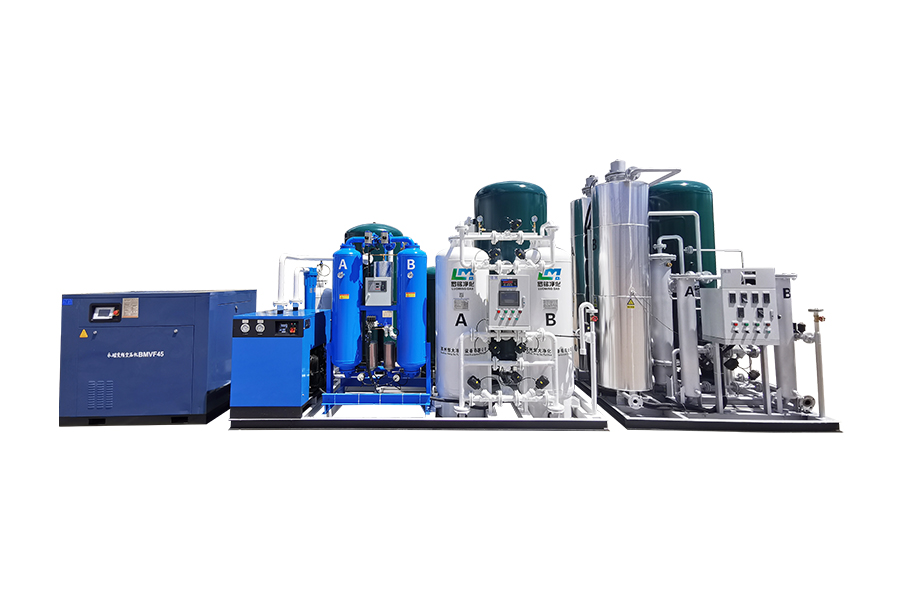

Jiangsu Luoming hydrogen plant utilizes advanced ammonia decomposition technology, consisting of a decomposition unit, purifier, and electrical control system. This system generates a clean mixture of 25% nitrogen and 75% hydrogen.

The mixed gas is primarily used as a protective atmosphere in industries such as metal heat treatment, electronics, powder metallurgy reduction, sintering, chemical manufacturing, and ceramics. For applications requiring high-purity hydrogen, a PSA (Pressure Swing Adsorption) system can be added, producing hydrogen with purity levels of ≥99.999%.

Product principle:

1. 2NH3 ----- 3H2 + N2

2. The ammonia decomposition hydrogen production plant uses liquid ammonia as raw material, and the gas is heated and decomposed under the action of catalyst to produce a mixture containing 75% hydrogen and 25% nitrogen. Pure hydrogen with purity of 99.999% can be further prepared by pressure swing adsorption method.

Structure and technology

- U-shaped or plum-shaped monolithic cracking furnace tube makes the flow of each part of the furnace uniform, uniform life, with external wire structure to maximize the thermal efficiency.

- The heat exchanger adopts the casing structure, and the large heat exchange area ensures the full utilization of thermal efficiency and long enough service life.

Unique material

- The furnace is made of rare high-temperature heat-resistant alloy material, which guarantees a long service life in high-temperature and highly corrosive environments. The heating element is made of nickel-chromium alloy with excellent mechanical properties at high temperature, and its surface load is determined in a reasonable range.

- The core insulation material aluminum silicate fiber is formed by the vacuum filtration method and the surface is strengthened more than five times, so it is light and has high strength; At the same time, its unique structure determines that the material coefficient is 15% lower than similar products.

Technical feature

1. Simple principle, compact structure, small footprint, easy to operate

2. Less investment, less energy consumption, low operating costs;

3. Widely used to meet most of the needs of hydrogen use;

4. Core components furnace body, furnace gall, electric heating wire optimization design, normal working conditions for three-year warranty;

5. When used with the gas purification device, the protective gas with high purity can be obtained.

Applications:

Oil-free bearing, powder metallurgy, bright annealing, sintering of electronic materials, sintering of high-temperature refractory materials, chemical industry, tin tank protection gas in float glass production, ceramic industry

English

English русский

русский Français

Français Español

Español عربى

عربى