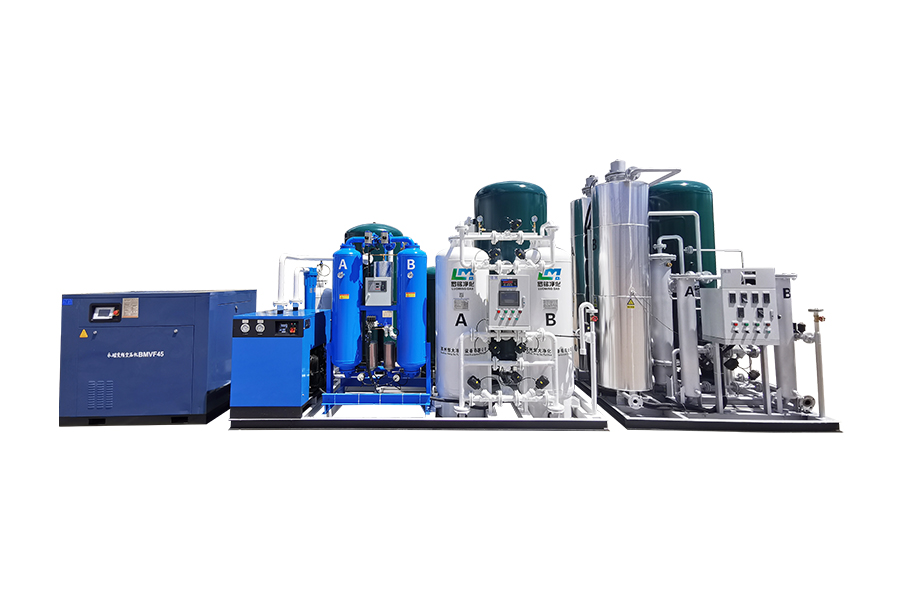

"Jiangsu Luoming" air filter is divided into C-class filter, T-class filter, A-class filter. We use a three-stage filter to remove liquid water, oil and solid particles from the compressed air, ensuring that the residual oil content is below 0.01ppm after being filtered through the three-stage filter. Depending on the use of the air separation system, customers need to replace the filter regularly.

Air Filter Types and Functions

C-Class Main Line Filter: Installed after the air compressor or before the refrigerated dryer, the C-Class filter effectively removes solid particles larger than 3 microns and a large amount of liquid. It achieves an impressive residual oil content as low as 5 ppm, ensuring clean air for downstream equipment.

T-Class Filter: Also known as an airline filter, this filter is positioned before the A-Class filters. It removes liquid and solid particles as small as 1 micron, with a residual oil content as low as 0.5 ppm, offering enhanced filtration for high-quality compressed air.

A-Class Filter: Known as the ultra-high efficiency oil removal filter, this is used after the refrigerated dryer. It filters out liquid and solid particles as small as 0.01 microns, achieving a remarkable residual oil content of just 0.001 ppm, making it ideal for applications requiring extremely clean air.

Importance of Using Genuine Parts

Using non-original parts in your compressor can compromise its performance and longevity. Such practices can lead to increased oil contamination in the compressed air, resulting in:

- The shortened service life of seals and valve gaskets.

- Higher electric power consumption, as excessive oil increases motor torque during startup and running conditions.

- Increased wear and tear on critical components like bearings and gears, can lead to premature failure.

- Reduced compressor efficiency, lowering the overall performance of your system.

English

English русский

русский Français

Français Español

Español عربى

عربى