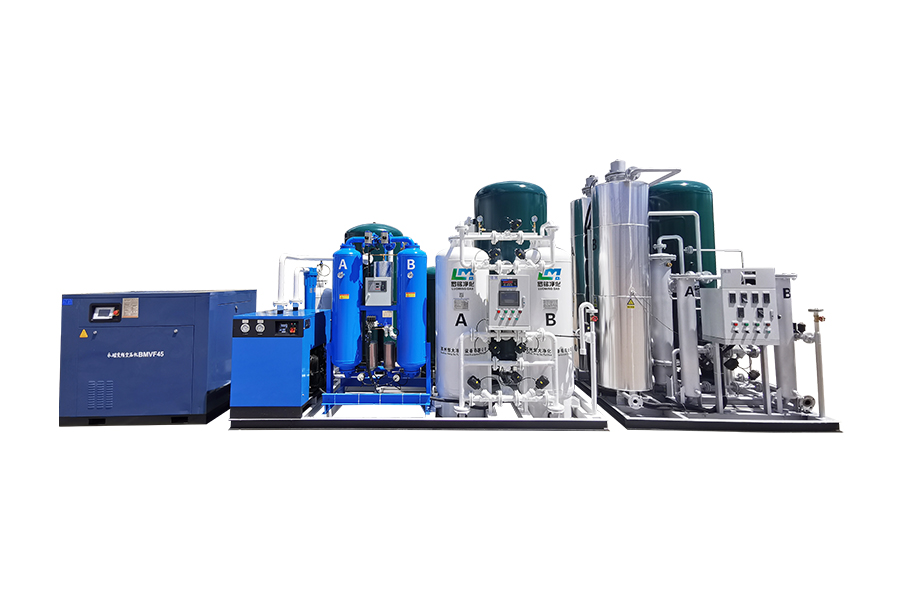

If the activated carbon is not replaced in time, it can lead to poor water removal and oil removal in the system. This allows a large amount of water, oil, and impurities to enter the adsorption tower, causing irreversible damage to the molecular sieve. If the carbon molecular sieve becomes poisoned by oil, it will lose its analytical ability entirely. As a result, the adsorption effect of the molecular sieve deteriorates, leading to reduced purity in the air separation system and decreased gas production. A degreasing agent serves as a crucial safety measure to prevent oil poisoning of the carbon molecular sieve. Therefore, the activated carbon filter is an essential component of the air purification system, ensuring optimal performance and efficiency.

Working Principle of Activated Carbon Filter

The activated carbon filter effectively removes oil mist and hydrocarbons as small as 0.01 microns, achieving a low residual oil content of just 0.003 ppm. It is widely used across industries such as food, pharmaceuticals, electronics, chemicals, and industrial wastewater treatment, providing efficient filtration for various applications.

Installation Points for Activated Carbon Filters

1. The filter meets the filtration accuracy requirements of the hydraulic system, preventing impurities from entering the system and ensuring smooth operation.

2. The filter elements should be robust enough to withstand pressure without damage.

3. The filter is designed for large flow capacity with low-pressure loss, optimizing system performance.

4. The activated carbon filter is easy to clean and replace, ensuring minimal downtime and long-term reliability.

English

English русский

русский Français

Français Español

Español عربى

عربى