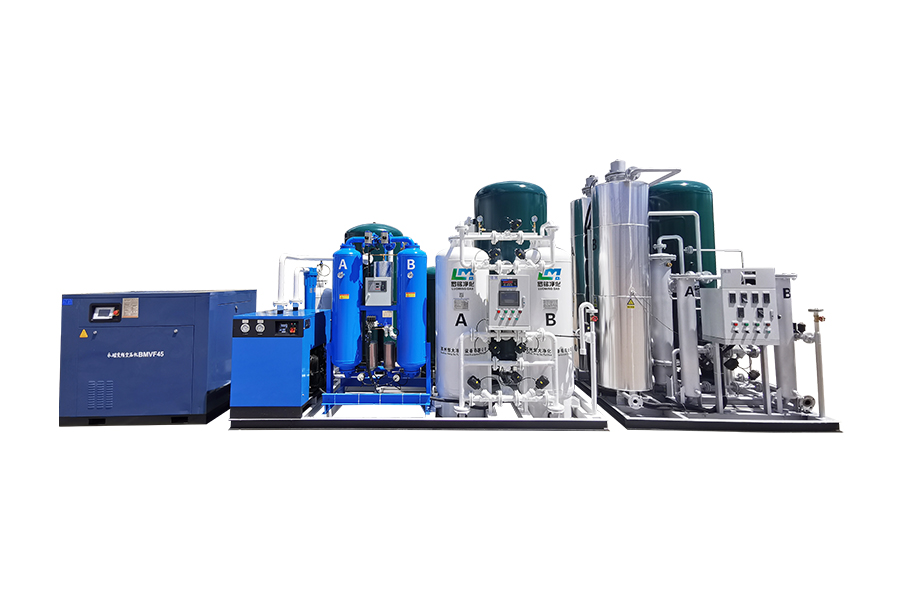

As auxiliary equipment of the air compressor, the air storage tank can store a certain amount of compressed air to ensure that the output of compressed air is stable while reducing the temperature in the air pipeline, removing moisture, dust, and impurities in the compressed air, etc., and also reducing the load of the dryer. The different pressures of the storage tank can be divided into high-pressure storage tank, low-pressure storage tank, normal pressure storage tank. It is used with air compressors, refrigerated dryers, filters and other equipment.

Working Principle of Air Storage Tanks

The air storage tank works by receiving compressed air from the compressor once it has reached a specified pressure. The stored air can then be released as needed through the discharge valve and pipeline, supplying the required equipment or system. Additionally, if the pressure inside the tank exceeds the set safety limit, the safety valve automatically opens to release excess air, preventing the risk of overload or potential explosion.

Advantages of Air Storage Tanks

- Storage of compressed air: Capable of storing large volumes of compressed air, ensuring a stable supply of pressure and power for various equipment.

- Pressure balance: Helps to balance system pressure, enhancing both the energy efficiency and overall stability of equipment operation.

- Reduced maintenance costs: By maintaining stable pressure, it reduces the wear and tear on equipment, prolonging service life and lowering maintenance costs.

English

English русский

русский Français

Français Español

Español عربى

عربى