Catalyst maintains stable activity and selectivity under high temperature and high pressure

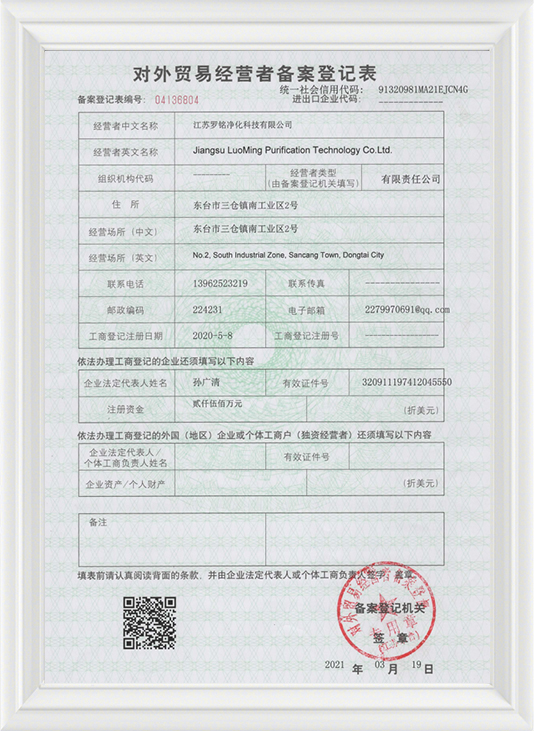

In the rapidly evolving field of gas separation and purification, maintaining catalyst performance under extreme conditions is a critical factor in ensuring process efficiency and product quality. Jiangsu Luo Ming Purification Technology Co., Ltd., established in May 2020 as a wholly-owned subsidiary of Suzhou Hengda Purification Equipment Co., Ltd., has emerged as a leading innovator in the development and production of high-performance gas-related equipment. With over 16,000 square meters of construction space dedicated to R&D, manufacturing, sales, and services, the company specializes in designing systems that operate reliably even under high temperature and high-pressure environments.

One of the key challenges in gas purification processes—especially those involving oxygen generation or hydrocarbon processing—is maintaining the stability and selectivity of catalytic materials. Catalysts are essential for facilitating chemical reactions that remove impurities, enhance gas purity, or enable energy-efficient separations. However, these catalysts often face degradation due to sintering, poisoning, or thermal stress when exposed to harsh operational conditions.

Jiangsu Luo Ming Purification Technology has successfully addressed this challenge through continuous innovation and strategic material selection. The company’s research team has developed advanced catalytic systems that remain stable and selective under high-temperature (up to 500°C) and high-pressure (up to 10 MPa) conditions. These catalysts are now integral components in several of the company's flagship products, including medical molecular sieve oxygen generators, aviation-grade high-purity oxygen generators, and medical compressed air systems.

Engineering Stability into Catalyst Design

The secret behind the superior performance of Luo Ming’s catalysts lies in their tailored composition and structural design. By employing high-surface-area supports such as alumina or zeolites and doping them with noble metals like platinum or palladium, the catalysts achieve enhanced thermal resistance and active site retention. Additionally, the use of nanoscale structures prevents particle agglomeration, which is a common cause of activity loss at elevated temperatures.

Moreover, Luo Ming’s engineers have optimized the pore structure of the catalysts to ensure efficient mass transfer and minimize diffusion limitations. This is particularly important in applications such as pressure swing adsorption (PSA), where rapid cycling between high and low pressures can place significant mechanical stress on catalytic materials. Through rigorous testing and simulation, the company ensures that its catalysts maintain both physical integrity and chemical reactivity throughout their lifecycle.

Application in Medical and Industrial Oxygen Systems

Jiangsu Luo Ming Purification Technology’s breakthrough in catalyst technology has significantly improved the performance of its medical oxygen generation systems. For instance, in medical molecular sieve oxygen generators, the catalyst plays a vital role in removing nitrogen oxides and other trace impurities from the feed air, thereby enhancing the purity and safety of the delivered oxygen. Thanks to the robustness of the catalyst, these systems can operate continuously in hospitals, clinics, and emergency care units without frequent maintenance or replacement.

Similarly, the company’s module oxygen generator and bunker oxygen system benefit from this advanced catalytic approach. In military or industrial settings where environmental conditions are unpredictable, maintaining consistent oxygen output is crucial. Luo Ming’s catalysts ensure that these systems perform reliably, even in high-humidity or high-altitude locations.

Aviation and Portable Oxygen Solutions

Beyond medical applications, Luo Ming has extended its expertise to aviation and portable oxygen solutions. The aviation high-purity oxygen generator, designed for use in aircraft and aerospace environments, requires catalysts capable of functioning under fluctuating pressure and temperature conditions. Luo Ming’s proprietary catalyst formulation enables the system to produce ultra-pure oxygen (>99.5%) consistently, meeting stringent international aviation safety standards.

Portable oxygen cylinders, widely used by patients with respiratory diseases and outdoor adventurers, also rely on compact catalytic filters to purify the ambient air before compression. Here, the catalyst must be not only effective but also lightweight and durable. Luo Ming’s innovations in miniaturized catalytic modules have made it possible to deliver high-quality oxygen in compact, battery-powered devices without compromising performance.

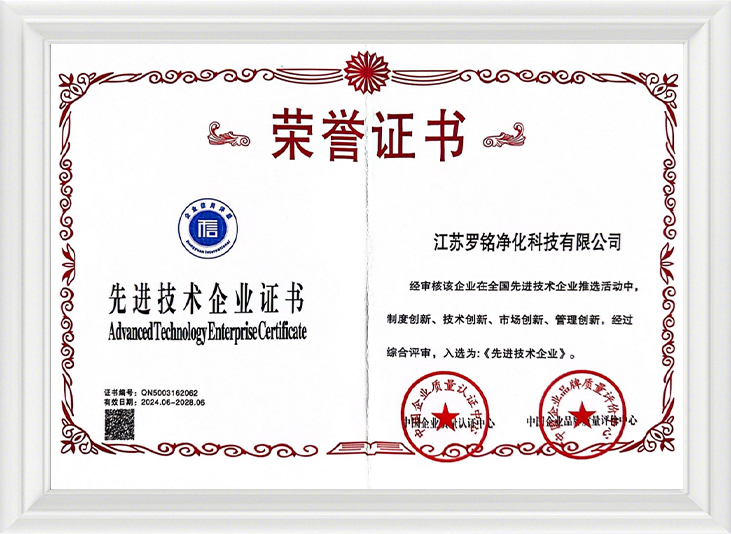

Commitment to Quality and Innovation

By the end of 2022, Jiangsu Luo Ming Purification Technology had obtained the Class II Medical Device Production License, underscoring its commitment to regulatory compliance and product excellence. This certification reflects the company’s ability to meet the highest standards in medical device manufacturing, including the reliability and safety of its catalytic components.

Furthermore, Luo Ming continues to invest heavily in R&D partnerships with universities and research institutions to explore new catalytic materials, such as perovskite-based oxides and metal-organic frameworks (MOFs), which hold promise for next-generation gas purification technologies. These efforts are aligned with global trends toward sustainability and energy efficiency, positioning Luo Ming at the forefront of the industry.

Jiangsu Luo Ming Purification Technology Co., Ltd. has demonstrated remarkable progress in developing catalysts that maintain stable activity and selectivity under high-temperature and high-pressure conditions. These advancements are not only enhancing the performance of existing gas purification systems but also opening new avenues for innovation in medical, industrial, and aerospace applications. As demand for reliable and high-purity gas solutions continues to grow, companies like Luo Ming will play a pivotal role in shaping the future of clean air technology.

English

English русский

русский Français

Français Español

Español عربى

عربى