How Advanced Automation Enhances Performance and Safety in Modern Hydrogen Generator Systems

In today's industrial environment, where precision, efficiency, and safety are top priorities, automation plays an increasingly critical role in hydrogen generator technology. Unlike earlier generations of equipment, which required manual oversight and intervention, modern hydrogen generator is equipped with intelligent control systems that elevate operational performance while reducing the risk of human error. These innovations are not just technical upgrades—they fundamentally reshape how industrial facilities manage gas production, paving the way for more consistent outputs and streamlined production processes.

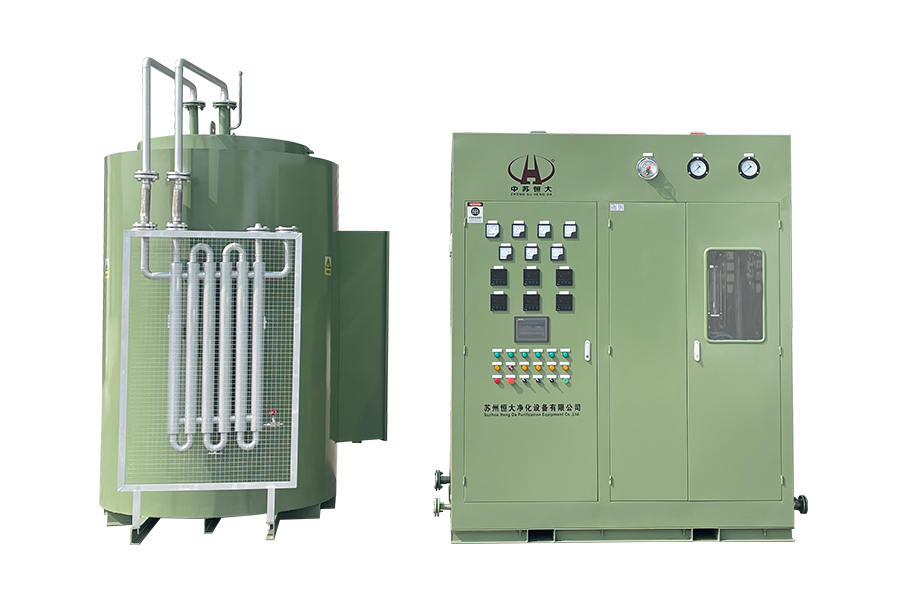

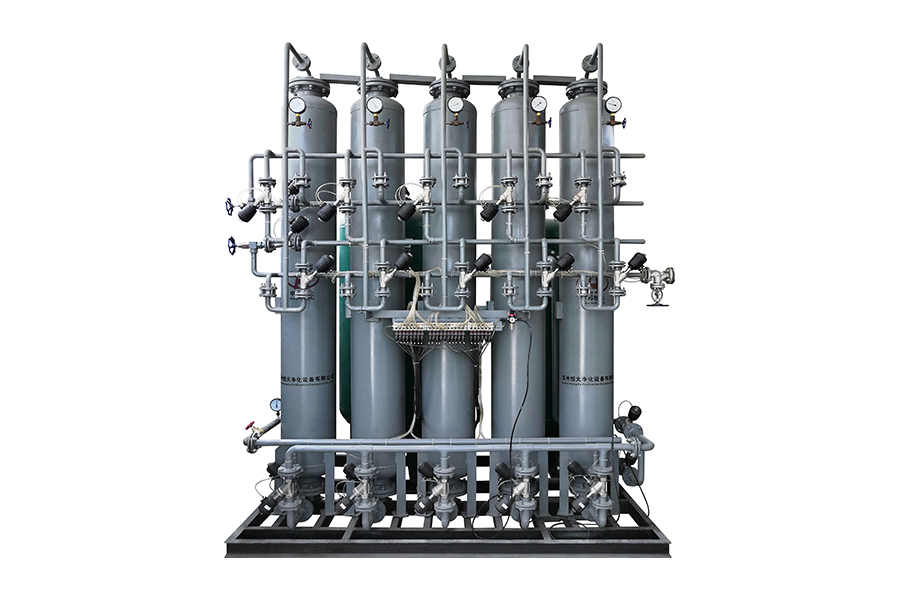

At the heart of these advancements is the integration of PLC-based control systems and advanced sensor networks. These components allow the hydrogen generator to self-regulate, monitor performance metrics in real time, and respond dynamically to operational changes. From gas purity and pressure regulation to temperature control and fault detection, automation enables a higher degree of process stability. It also ensures that even in fluctuating production environments, the generator can adjust seamlessly without compromising output quality or safety.

A particularly valuable benefit is the reduction in required operator intervention. For industries where uptime is critical and technical personnel are often stretched thin, automated hydrogen systems mean less time spent on routine adjustments and troubleshooting. Intelligent alerts and diagnostics make it easy to detect anomalies early, while remote access capabilities allow technicians or engineers to monitor performance and make adjustments from a distance. This not only saves manpower but also enables more proactive maintenance strategies that extend equipment life and reduce unplanned downtime.

Automation also significantly enhances safety, a key concern when working with flammable gases. Hydrogen generator that incorporate automatic shut-off systems, leak detection, and continuous fault monitoring help create a safer working environment. In the event of a system irregularity, the generator can initiate predefined safety responses—such as venting, cooling, or emergency shutdown—without waiting for human input. These features, which are increasingly becoming industry standard, reflect a broader trend toward risk mitigation through intelligent engineering.

From a user perspective, the ease of operation is another major advantage. Touchscreen interfaces, real-time performance dashboards, and step-by-step operational guidance make even complex systems accessible to non-specialist staff. Whether the hydrogen generator is deployed in an electronics facility, metal processing plant, or lab-scale production line, these user-friendly controls reduce the training burden and lower the entry threshold for operators. This design philosophy reflects the manufacturer’s focus on delivering not just high-performance equipment, but also practical tools that fit into the realities of industrial workflows.

For manufacturers like us at Jiangsu Luoming Industrial, developing fully automated hydrogen generators is not just about adopting the latest technology—it’s about solving real problems for our clients. We understand that efficiency alone isn't enough; reliability, compliance, and ease of integration are equally critical. That’s why our systems are designed with modular architecture and can be easily incorporated into existing production lines or scaled as demand grows. It's a solution built for today’s dynamic industrial needs.

As digital transformation accelerates across industries, the demand for smart, connected, and autonomous systems will only grow. A high-quality hydrogen generator equipped with advanced automation is no longer a luxury—it’s a strategic asset. Forward-thinking companies are already leveraging these technologies to reduce operational costs, ensure consistent gas purity, and maintain regulatory compliance with minimal manual oversight. The result is not just a more efficient production process, but also a safer and more resilient one.

In short, the shift toward automation in hydrogen generation reflects a larger evolution in industrial gas technology. With a focus on control, connectivity, and continuous performance, automated systems are setting new benchmarks for what a hydrogen generator can deliver. For businesses aiming to modernize and future-proof their operations, now is the time to invest in solutions that combine technological innovation with proven industrial expertise.

English

English русский

русский Français

Français Español

Español عربى

عربى