Why More Industries Trust Ammonia Decomposition Hydrogen Generators for Consistent Gas Supply

Understanding the Technology Behind Ammonia Decomposition

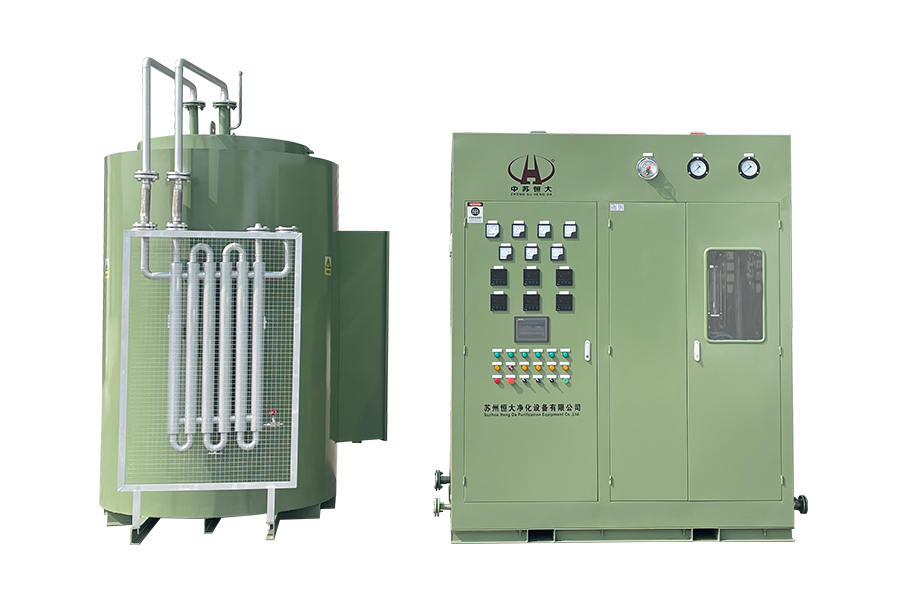

An Ammonia Decomposition Hydrogen Production Device works by thermally cracking ammonia (NH₃) into its constituent gases: hydrogen (H₂) and nitrogen (N₂). The process typically yields a gas mixture composed of 75% hydrogen and 25% nitrogen. This blend is ideally suited for creating protective atmospheres in heat treatment processes, sintering, and the reduction of metal powders. Industries that require a controlled environment for materials processing are particularly reliant on this gas composition, which ensures product quality while minimizing oxidation and contamination.

Compared to other hydrogen generation technologies such as water electrolysis or natural gas reforming, ammonia decomposition offers a relatively low-cost and straightforward alternative. The process requires no water, no complex infrastructure, and can be operated with compact equipment designs that are scalable depending on the hydrogen demand.

Industrial Applications of Ammonia Decomposition Gas

One of the primary reasons why more industries are turning to Ammonia Decomposition Hydrogen Production Device is their versatility. The hydrogen-nitrogen gas mixture produced is particularly beneficial for:

Metal heat treatment, where a non-oxidizing atmosphere is needed to harden, temper, or anneal components without surface degradation.

Electronics manufacturing, where sensitive processes depend on ultra-clean environments and reducing gases.

Powder metallurgy, including sintering and reduction stages where controlled atmospheres influence grain structure and product integrity.

Ceramic production, especially for technical ceramics where hydrogen is used to reduce metal oxides.

Chemical synthesis, where hydrogen serves as a key reactant in forming various compounds.

Moreover, for applications that demand higher hydrogen purity, Ammonia Decomposition Hydrogen Production Device can be integrated with a PSA (Pressure Swing Adsorption) system. This optional unit selectively adsorbs nitrogen and other trace gases, producing hydrogen with purities reaching up to 99.9995%. This capability significantly broadens the range of industries that can utilize the technology, including those in high-purity hydrogen applications such as laboratory gas supply, semiconductor production, and hydrogen fuel generation.

Jiangsu Luoming: Engineering Clean Hydrogen Solutions

One of the notable companies advancing this technology is Jiangsu Luo Ming Purification Technology Co., Ltd., a company that has gained recognition for its integrated approach to gas equipment engineering. As a wholly-owned subsidiary of Suzhou Hengda Purification Equipment Co., Ltd., Jiangsu Luoming brings together research and development, manufacturing, sales, and customer service within a production area of over 16,000 square meters.

Since its establishment in 2020, Jiangsu Luoming has expanded its capabilities not just in ammonia decomposition, but across a broad portfolio of gas-related systems. These include oxygen generators, medical compressed air systems, and aviation-grade high-purity oxygen devices. The company's diversification and deep technical experience have provided a strong foundation for refining and producing reliable Ammonia Decomposition Hydrogen Production Devices that meet the evolving needs of various industries.

The company’s design philosophy emphasizes modular construction, energy efficiency, and intelligent control. Each hydrogen production system typically includes a decomposition furnace, purification equipment, and a fully automated electric control system that ensures operational safety, precise temperature regulation, and consistent output gas quality. The integration of these features helps minimize human error, reduce downtime, and improve long-term system stability—factors that are critical in industrial environments where gas interruptions can lead to costly disruptions.

A Trustworthy Alternative in Unstable Markets

Another key advantage of ammonia-based hydrogen generation lies in the relative stability and availability of ammonia as a feedstock. Unlike natural gas or electricity, which are subject to market volatility, ammonia is widely traded and can be stored with high energy density. This makes the Ammonia Decomposition Hydrogen Production Device not only an operationally consistent solution, but also one that insulates manufacturers from supply chain shocks and price fluctuations commonly seen in global energy markets.

Given the increasing global focus on energy security, decarbonization, and process optimization, ammonia decomposition is also gaining interest as a transitional solution in hydrogen energy roadmaps. By using existing ammonia infrastructure, companies can gain early access to hydrogen technologies without the need for massive new capital investments.

Conclusion

The rise in adoption of the Ammonia Decomposition Hydrogen Production Device reflects a broader shift toward cleaner, more stable, and more adaptable hydrogen supply strategies in industrial environments. With its capability to deliver a consistent gas mixture for protective atmospheres, its flexibility to achieve ultra-high purity levels, and its economic and technical efficiency, this technology continues to gain the trust of industries worldwide.

Companies like Jiangsu Luoming are leading this transformation with engineering expertise, integrated services, and proven systems that meet the stringent requirements of today’s manufacturing standards. As hydrogen continues to play a pivotal role in industrial and energy applications, ammonia decomposition will likely remain a cornerstone of dependable hydrogen generation.

English

English русский

русский Français

Français Español

Español عربى

عربى