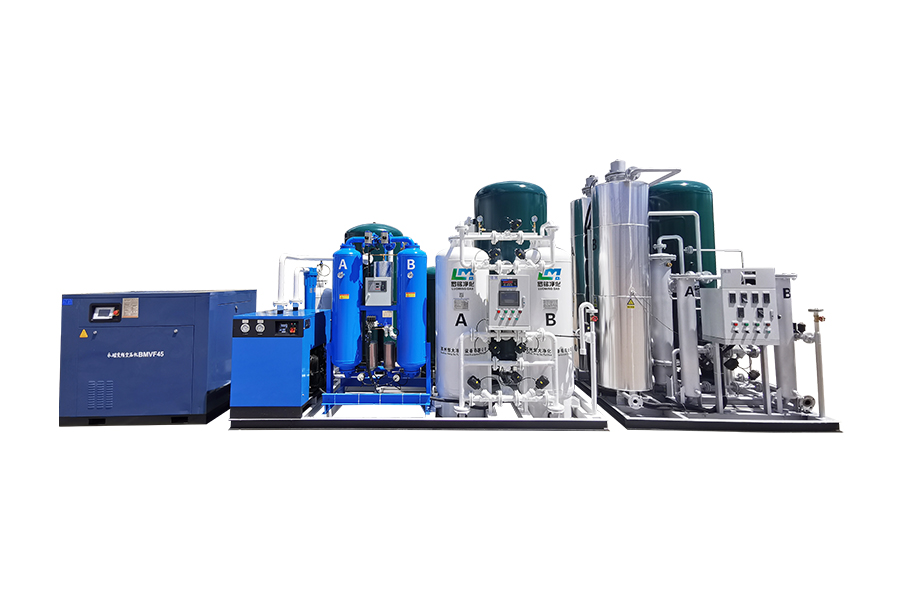

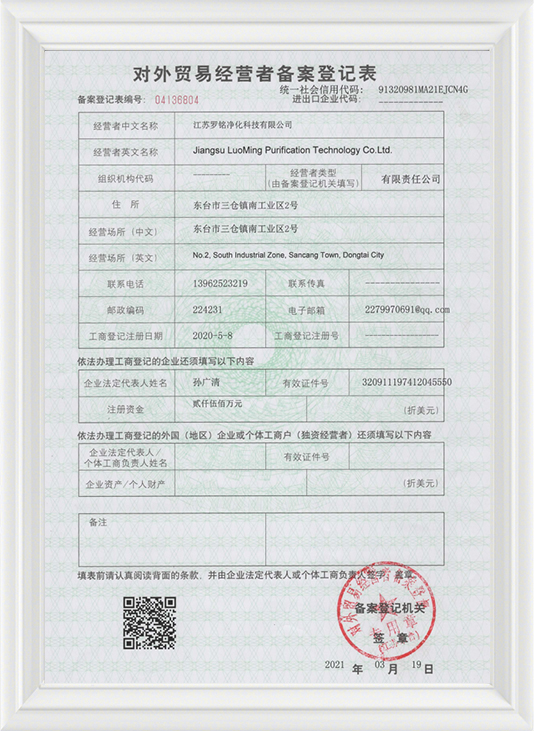

Jiangsu Luoming Purification Technology Co., Ltd. specializes in the research and manufacturing of medical molecular sieve oxygen generators. With core technologies such as pressure swing adsorption (PSA) separation, the company's products are renowned for their efficiency, safety, cost-effectiveness, and convenience. OEM Medical Oxygen Generation Plant.

LMFC Series Carbon Purification Nitrogen Generator

PSA Nitrogen Generator

Nitrogen Filling Equipment

Trailer Type Portable PSA Nitrogen Generator

Cabinet Type Van Box Type PSA Nitrogen Generator

Container Type PSA Nitrogen Generator

Chassis type box type PSA Nitrogen Generator

High Purity PSA Nitrogen Generator

Industry PSA Nitrogen Generator

LMDC99.999-80 Nitrogen Production And Purification Device

5 Cubic Medical Oxygen Generator

Containerized 10 Cubic Meter Oxygen Generator

We focus on the field of environmental protection technology, providing efficient solutions such as air purification, water treatment and waste gas treatment. Profrssional OEM Oxygen Gas Plant and Custom Medical Oxygen Plant in China. Its products are widely used in hospitals, laboratories, electronic manufacturing, food processing and chemical industries, covering high-efficiency filters, reverse osmosis equipment, waste gas treatment systems, etc. The company helps various industries achieve green and sustainable development with innovative technology and high-quality services. Supply Custom Medical Oxygen Generation Plant

Jiangsu Luoming Purification Technology Co., Ltd., a wholly-owned subsidiary of Suzhou Hengda Purification Equipment Co., Ltd., is proud to announce that its advanced Aquaculture Oxygen Generator System Provider solution...

View MoreRecently, Jiangsu Luoming Purification Technology Co., Ltd. (hereinafter referred to as "Luoming Purification") organized a three-day team building activity for all all its sales department employees in Tonglu, Zhejiang ...

View MoreInstalling a Medical Oxygen Generator (MOG) is a significant step toward achieving a reliable, on-site oxygen supply for any healthcare facility. While the operational benefits—independence from cylinder logistics, long-...

View MoreJiangsu Luoming Purification Technology Co., Ltd., recognized for its PSA Nitrogen Generator for Laser Cutting Machine solutions and holding the prestigious High-Tech Enterprise Certificate continues to set new benchmark...

View MoreWhat Are the Main Applications of Medical Oxygen Plant from Jiangsu Luoming Purification Technology Co., Ltd.?

In an era where reliable medical oxygen supply is critical, Jiangsu Luoming Purification Technology Co., Ltd. stands at the forefront of innovation, specializing in Pressure Swing Adsorption (PSA) oxygen generation systems. As a trusted OEM manufacturer, the company integrates cutting-edge environmental technologies with precision engineering to deliver high-purity medical and industrial oxygen solutions.

Core Expertise: Advanced Oxygen Generation & Environmental Solutions

Jiangsu Luoming Purification Technology excels in PSA-based oxygen production, offering systems that are energy-efficient, cost-effective, and compliant with stringent medical standards. Medical Oxygen Generation Plant, the company provides air purification, water treatment, and waste gas management systems, supporting industries in achieving sustainable and eco-friendly operations.

Key Applications of Oxygen Gas Plant

1. Healthcare & Hospital Oxygen Supply

Medical facilities require uninterrupted, high-purity oxygen for critical care, surgical procedures, and respiratory therapies. Luoming’s PSA oxygen generators ensure:

On-site oxygen production, eliminating dependency on cylinder logistics.

93%± purity levels, meeting ISO 13485, CE, and FDA standards for medical use.

Scalable solutions for ICUs, emergency wards, and field hospitals.

2. Laboratories & Pharmaceutical Manufacturing

Precision gas supply is vital in research labs, drug development, and biotech applications. Luoming’s systems provide:

Contaminated-free oxygen for sterile environments.

Stable pressure and flow control for sensitive instruments.

Custom configurations for GMP-compliant pharmaceutical production.

3. Industrial & Specialty Gas Applications

Beyond healthcare, Luoming’s oxygen plants serve high-tech and industrial sectors:

Electronics Manufacturing: Ultra-pure oxygen for semiconductor fabrication and LED production.

Food & Beverage Processing: Modified Atmosphere Packaging (MAP) to extend shelf life.

Chemical & Petrochemical Industries: Oxygen-enriched combustion and waste gas treatment.

Why Choose Jiangsu Luoming’s Oxygen Solutions?

OEM/ODM Flexibility: Tailored systems for niche medical and industrial demands.

Energy-Efficient PSA Technology: Lower operational costs compared to cryogenic distillation.

End-to-End Support: From design and installation to maintenance and compliance certification.

Conclusion: A Partner for Sustainable Oxygen Solutions

Jiangsu Luoming Purification Technology Co., Ltd. bridges the gap between medical necessity and industrial innovation, delivering reliable, scalable, and eco-conscious oxygen generation systems. Whether for hospitals, labs, or high-tech manufacturing, their solutions ensure uninterrupted supply, regulatory compliance, and operational efficiency.

For industries seeking bespoke oxygen plants or environmental purification systems, Luoming’s expertise offers a future-ready answer.