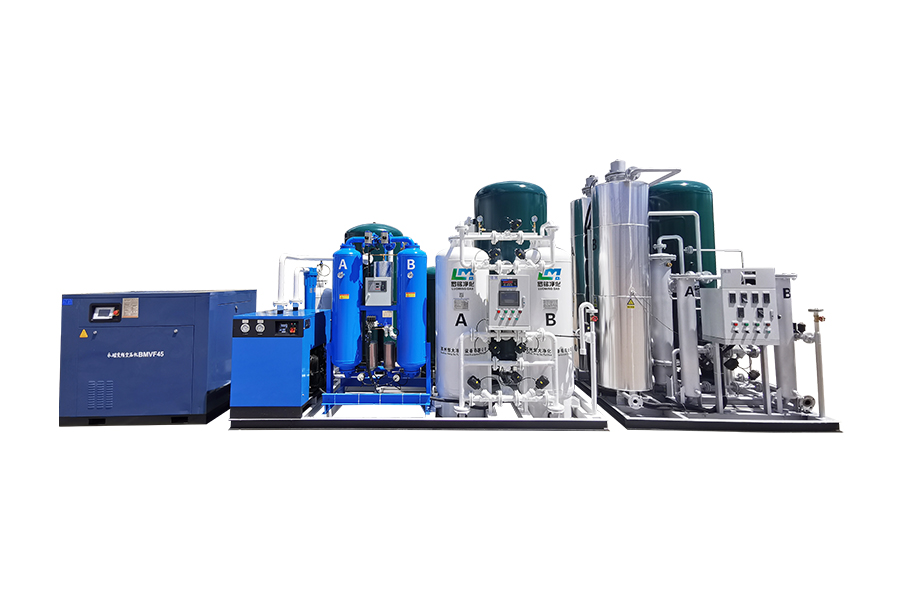

The LMDC99.999-80 nitrogen production and purification device is a specialized device focused on nitrogen supply for fabric production. Its core function is to provide nitrogen with a purity of 99.999% for fabric processing, with a stable flow rate of 80 Nm³/h.

The device utilizes pressure swing adsorption (PSA) technology, using a specialized carbon molecular sieve to absorb impurities such as oxygen and carbon dioxide from the air. This eliminates the need for additional chemical reagents and prevents contamination of fabrics. Its purification system features a three-stage filtration system that deeply removes trace moisture and oil mist from the nitrogen, ensuring a nitrogen dew point below -40°C, meeting the production requirements of high-precision fabrics such as functional chemical fibers and medical protective fabrics.

Designed for fabric production workshops, the device features a dust-proof enclosure to withstand the dusty conditions common in these workshops. With a footprint of only 2.5 square meters, it can be flexibly positioned next to the production line. The operator panel integrates a one-touch start/stop function, and operating noise is below 65 decibels, minimizing disruption to normal workshop operations. In terms of maintenance, the equipment's filter element replacement cycle is clearly marked as 2,000 hours, and the carbon molecular sieve has a service life of up to 8,000 hours. A consumables remaining warning function is also included, allowing users to plan maintenance downtime in advance and minimize the impact on production schedules.

English

English русский

русский Français

Français Español

Español عربى

عربى