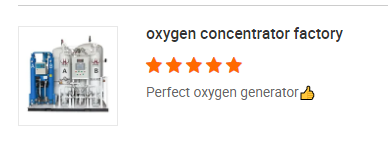

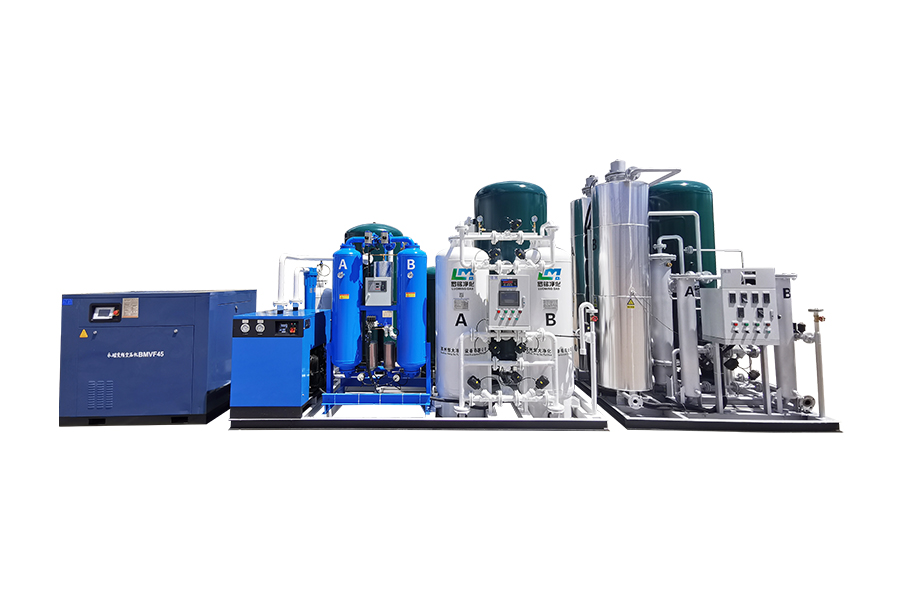

This containerized 10 cubic meter oxygen concentrator utilizes core components that are proven in the industry. Its compressor utilizes a low-noise, reciprocating design, resulting in minimal vibration during operation. This design adapts to the enclosed space of a container and reduces losses caused by equipment resonance.

The molecular sieve modules utilize a columnar packing process and utilize zeolite materials with stable adsorption properties. A layered arrangement improves nitrogen adsorption efficiency, ensuring consistent oxygen production that meets medical standards.

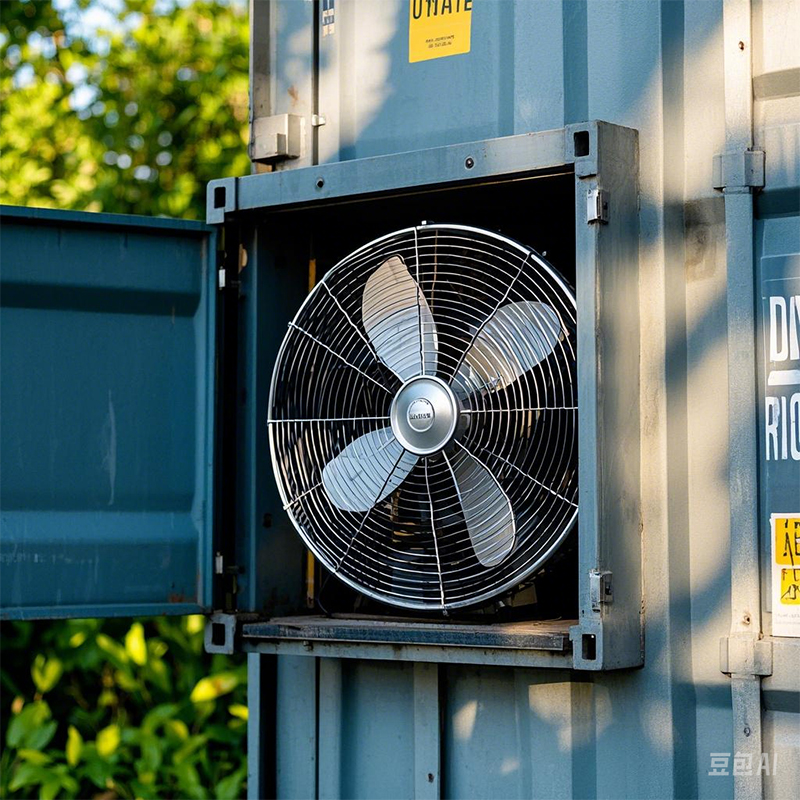

The device's cooling system is integrated into the container's sidewall, combining forced air cooling with natural heat dissipation. The optimized spacing of the heat sink fins allows for extended operation in high-temperature environments, preventing performance degradation due to overheating.

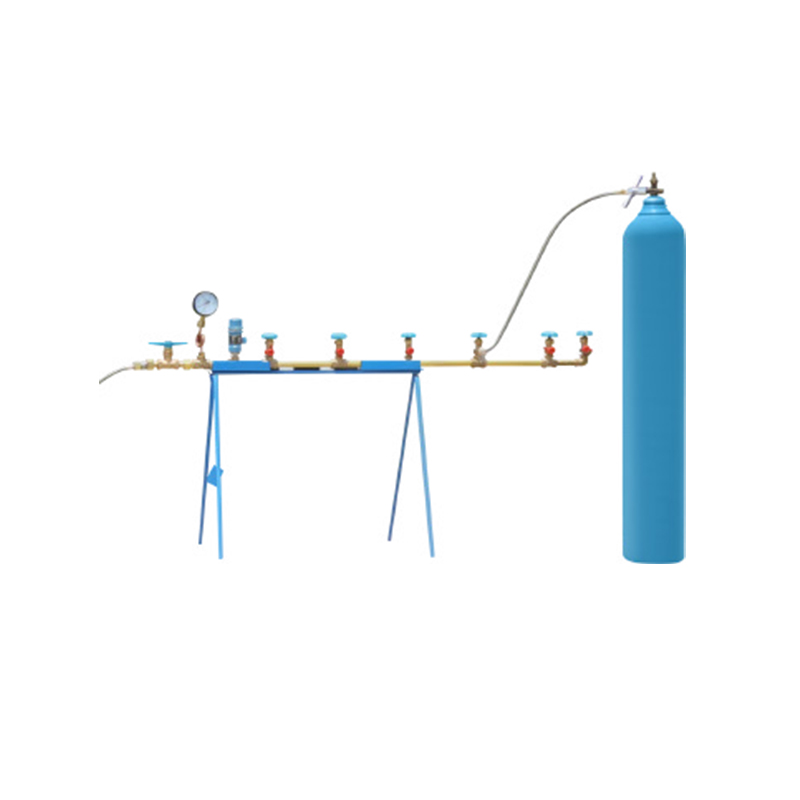

Internal piping utilizes corrosion-resistant copper tubing, with sealing gaskets at joints to minimize the risk of gas leakage. The control panel, embedded in the container's side door, features a simple user interface that includes basic functions such as flow rate display and pressure monitoring, making it easy for on-site personnel to quickly learn how to use the device.

The overall structure conforms to standard container dimensions, allowing for forklift loading and unloading. The bottom bracket features mounting brackets, making it suitable for diverse transportation and temporary placement.

English

English русский

русский Français

Français Español

Español عربى

عربى