Choosing Between Three-Stage and Four-Stage Compression in Gas Booster for Optimal Performance

When selecting industrial gas boosters for applications involving oxygen or nitrogen, one of the core engineering decisions revolves around whether to choose a three-stage or four-stage compression design. This isn't just a question of how many cylinders are stacked in the system—it's about striking a careful balance between pressure requirements, flow rate stability, thermal efficiency, and long-term equipment performance. At Jiangsu Luoming, we’ve seen firsthand how understanding the nuances of multi-stage compression can help customers avoid underperformance and costly system mismatches.

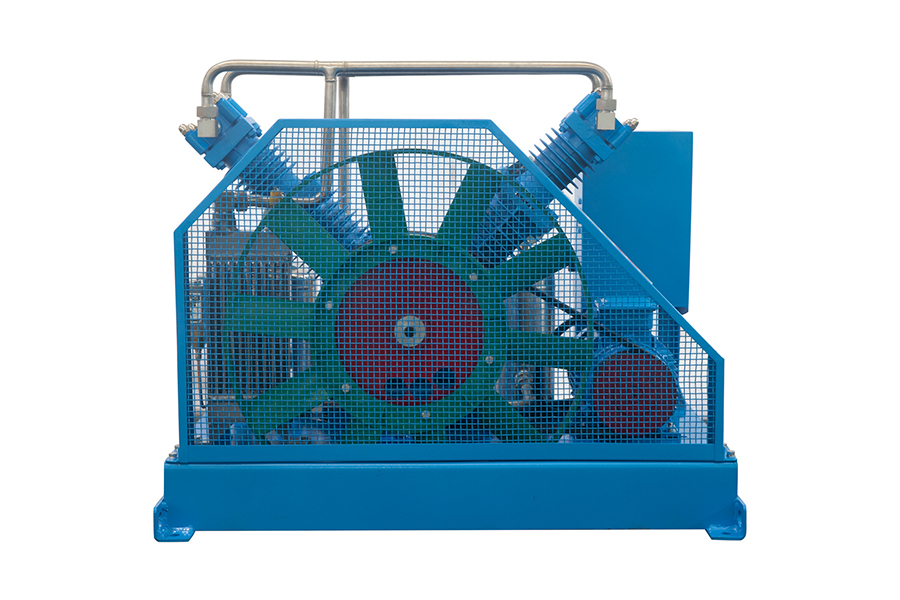

In a three-stage gas booster, the gas is compressed incrementally across three chambers, each designed to handle a specific pressure increase. This setup is typically more compact and can often meet mid-to-high pressure requirements with fewer components. For applications where space efficiency and lower capital cost are priorities, three-stage systems offer a good return. However, when the required final discharge pressure is particularly high or the process is continuous and heavy-duty, the limits of three-stage designs start to show—especially in terms of heat accumulation and mechanical stress.

That’s where four-stage compression systems gain an edge. By distributing the compression workload across an additional stage, each cylinder operates with a lower compression ratio, resulting in reduced thermal strain and smoother pressure transitions. This design not only improves the thermal efficiency of the booster but also enhances the durability of internal components such as the piston rings and valves. In systems that require ultra-clean or high-purity gas—such as medical oxygen supply or semiconductor-grade nitrogen—this added control over heat and pressure stability can be critical for ensuring consistency and gas integrity.

Another important consideration is gas flow rate. While both three-stage and four-stage boosters can achieve similar pressure targets, a four-stage configuration often maintains more stable flow over longer operational periods. This becomes a significant advantage in production environments where constant, uninterrupted gas delivery is essential. Moreover, in oil-free gas booster like those we manufacture, stage design plays a crucial role in minimizing mechanical wear without sacrificing output. Fewer stages can mean more mechanical strain, whereas spreading the compression across four stages can lengthen service life with minimal maintenance.

From a control perspective, four-stage boosters also tend to offer finer adjustment potential, which benefits customers who need highly customized pressure profiles. That said, not every application demands that level of precision. In many industrial setups—like nitrogen-assisted laser cutting or general-purpose oxygen supply—a well-configured three-stage system is more than sufficient. This is where a tailored recommendation from an experienced manufacturer becomes invaluable. We take pride in offering specific guidance based on actual operating conditions rather than one-size-fits-all advice.

It’s also worth noting that the structural differences influence cooling needs. A four-stage gas booster generally runs cooler, which reduces the burden on auxiliary cooling systems and increases energy efficiency. This has become more relevant in today’s energy-conscious manufacturing landscape, where operational cost and sustainability goals are often just as important as equipment reliability. In fact, we’ve worked with several clients who’ve switched from three-stage to four-stage systems not because of pressure limits, but due to the long-term gains in performance stability and lower downtime.

Ultimately, whether a customer chooses a three-stage or four-stage gas booster depends on a host of interrelated factors: target pressure, duty cycle, gas purity level, cooling conditions, and operational scale. There’s no absolute “better” option—just the better fit. Our sales and engineering teams work closely with buyers to evaluate these parameters and propose the most suitable solution. For companies looking to upgrade or expand their pressurized gas systems, understanding the distinction between these two designs is a smart first step toward improved reliability and system efficiency.

At Jiangsu Luoming, we combine technical expertise with real-world application experience to help customers make confident decisions about their gas compression equipment. Whether you're scaling up a new production line or retrofitting an older system, our oil-free gas boosters—available in both three-stage and four-stage variants—are built to deliver clean performance, durable operation, and long-term value.

English

English русский

русский Français

Français Español

Español عربى

عربى