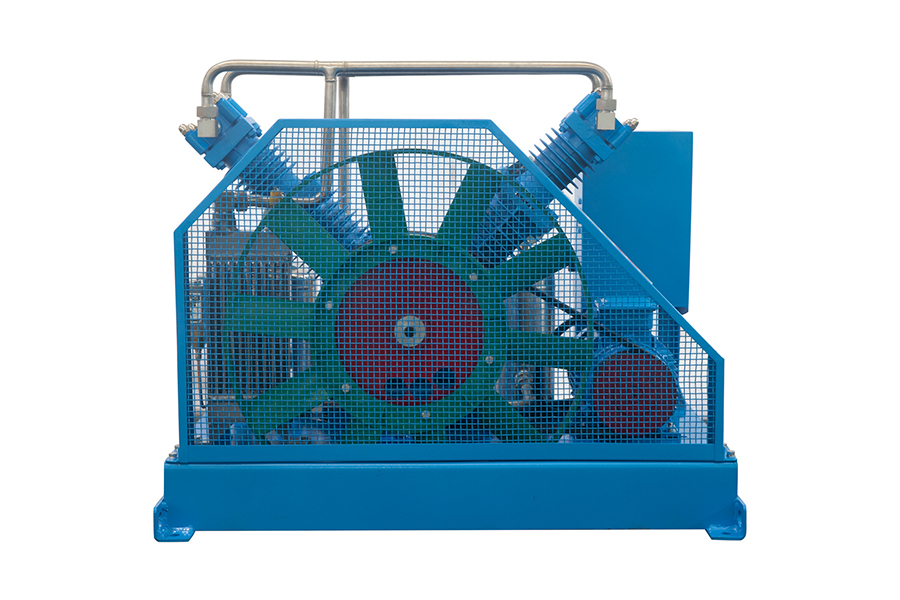

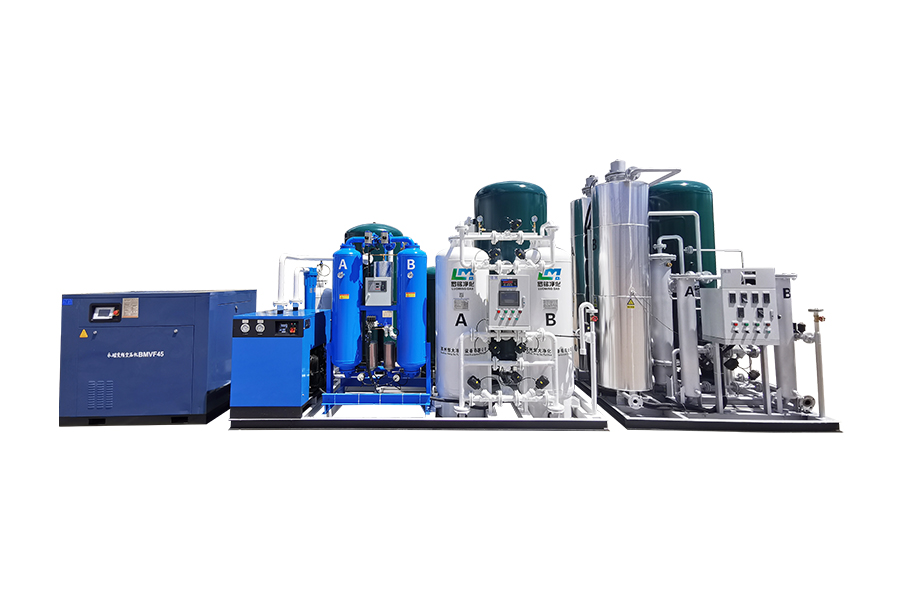

The oxygen booster from Jiangsu Luoming is typically categorized into high-pressure oxygen boosters and medium/low-pressure oxygen boosters. The high-pressure oxygen booster is primarily used in oxygen filling systems (also known as oxygen charging stations), while the low-pressure oxygen booster is commonly employed in ready-to-use oxygen generator systems.

Oxygen is a violent accelerant that can easily cause combustion and explosion. Special care should be taken when designing and using oxygen compressors: contact of compressed gas components with oil is strictly prohibited, oil is not contaminated during maintenance, and it must be cleaned with solvents before assembly.

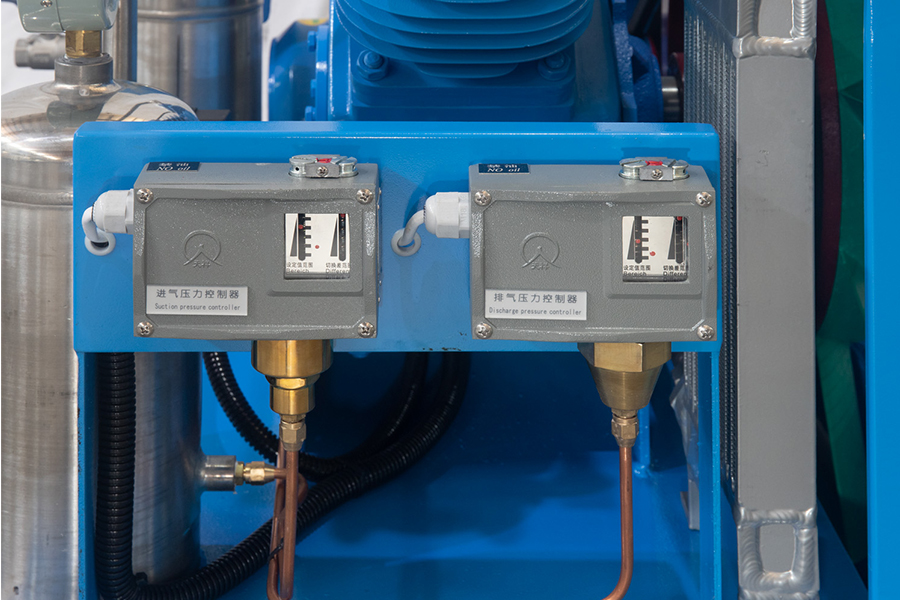

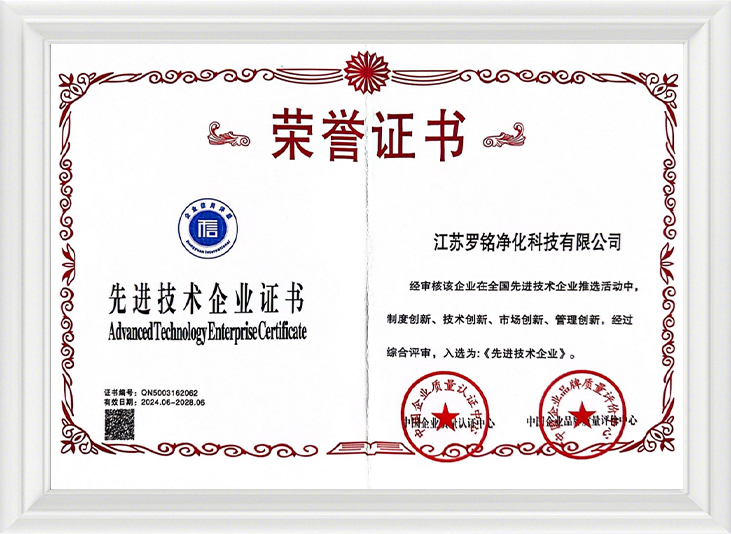

The oil-free oxygen booster system from Jiangsu Luoming adheres to stringent oxygen cleaning standards, ensuring that every component in contact with gas is meticulously cleaned and thoroughly documented. This is a fully oil-free oxygen compressor, eliminating the need for lubricating oil. It utilizes a packing sealing method, operates at low speeds, and features a long-lasting piston ring, ensuring durability and preventing any contamination to the oxygen.

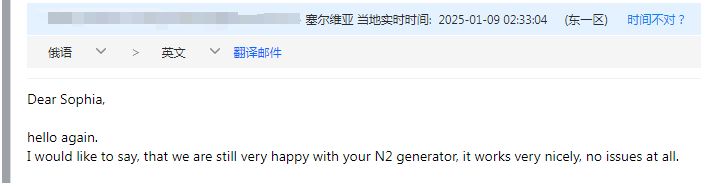

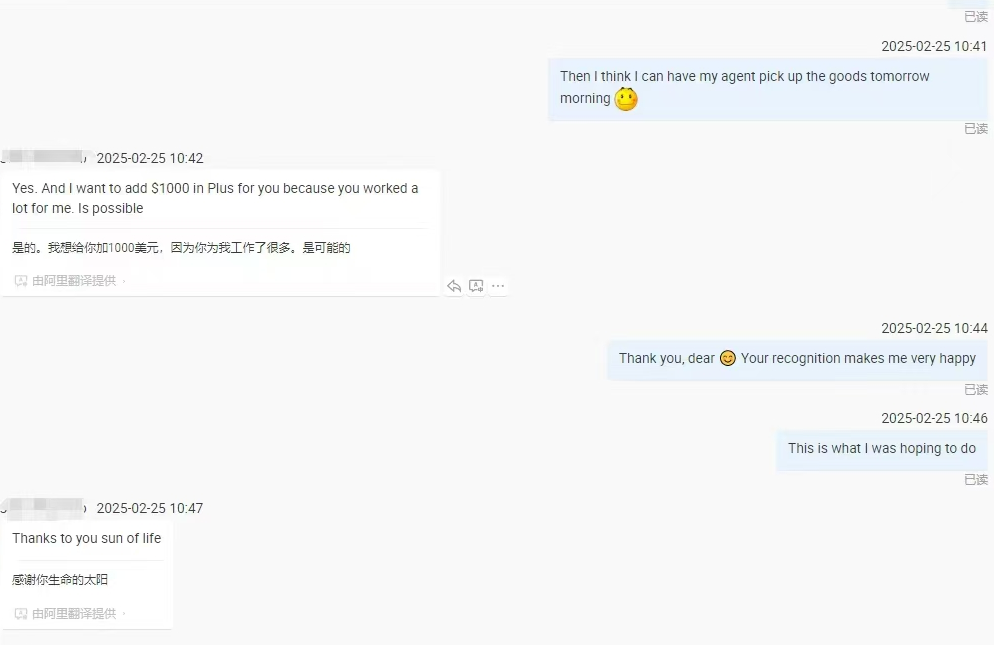

Customer-Specific Features:

1. Oxygen pressurization for PSA gas sources to optimize performance.

2. Pollution-free operation, maintaining the same oxygen purity as the gas inlet.

3. Stable and reliable quality, comparable to internationally imported brands.

4. Low procurement and maintenance costs, with simple operation.

5. The system is customizable based on customer needs, offering single-stage, two-stage, three-stage, or four-stage compression options.

6. Low speed, long operational life with an average speed range of 260-400 RPM.

7. Low noise operation, with average noise levels below 75 dB, making it suitable for use in medical environments.

8. Capable of continuous heavy-load operation, running reliably for 24 hours a day without interruption.

English

English русский

русский Français

Français Español

Español عربى

عربى