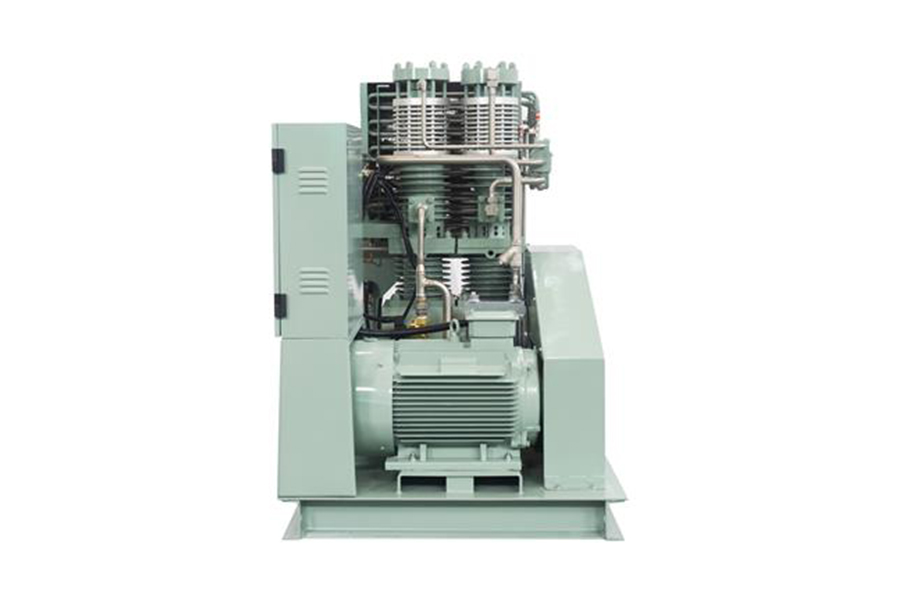

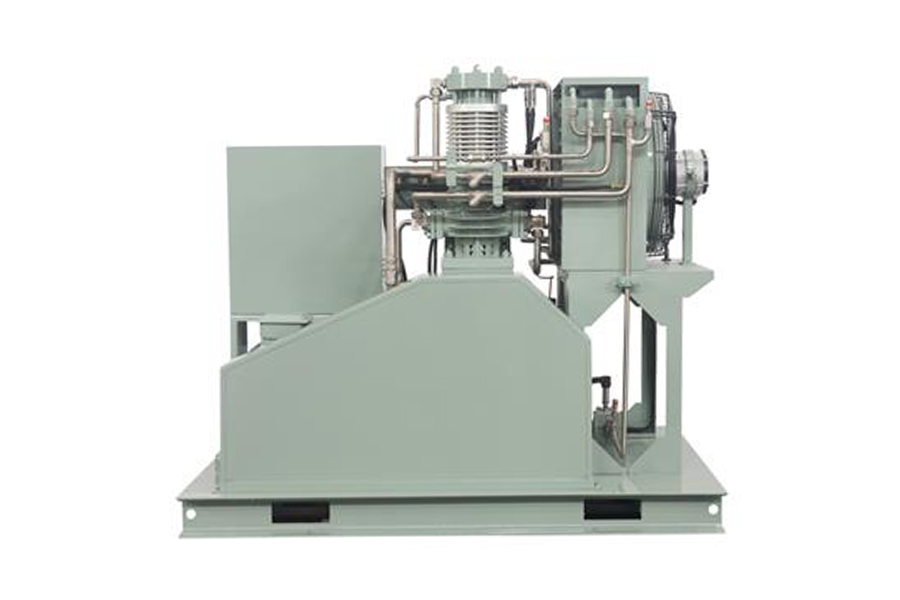

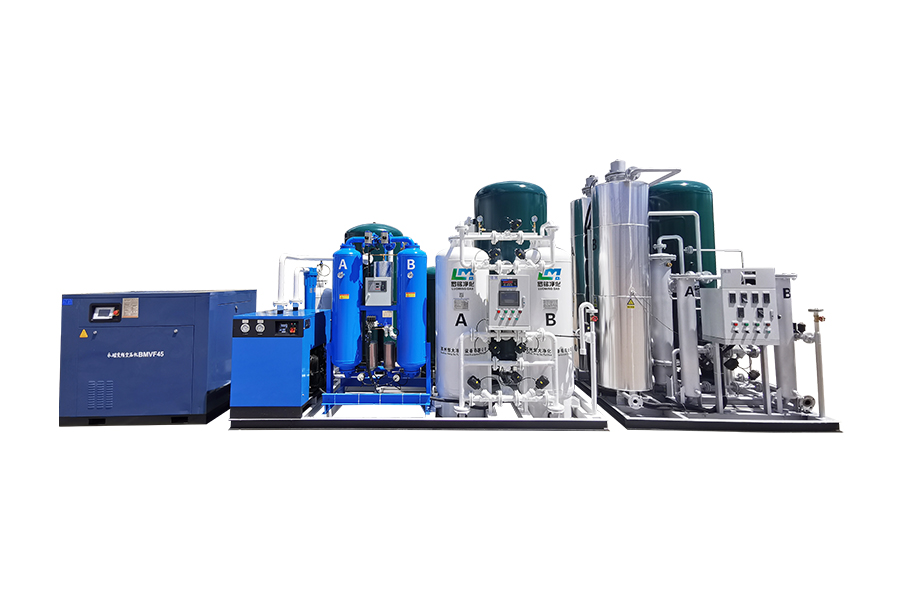

The nitrogen booster is a compressor designed to pressurize nitrogen for delivery or storage. The nitrogen boosters from Jiangsu Luoming are available in low-pressure oil-free and high-pressure oil-free versions, with customizable pressure options to meet customer needs.

They are primarily used for pressurizing and filling nitrogen cylinders, as well as performing nitrogen pressure tests and leakage measurements in pipelines. The maximum filling pressure can reach 40MPA. Depending on the cooling method, the boosters are available in air-cooled or water-cooled versions and can be configured with three-stage or four-stage compression. With completely oil-free lubrication, the boosters eliminate the risk of oil contamination in high-pressure, high-purity nitrogen, ensuring that the purity of nitrogen at both the inlet and outlet remains the same.

The nitrogen booster compressor of “Jiangsu Luoming” is the compressor used to pressurize nitrogen and transport or store nitrogen. It is mainly used for the pressurization filling of nitrogen cylinders and the nitrogen pressure leakage test of pipelines, etc. The maximum filling pressure can reach 40MPA. It is divided into air cooling and water cooling according to the cooling method.

Characteristic

No oil, green pollution, no need to lubricate.

Friction seals such as piston rings and guide rings are made of special materials with self-lubricating properties and do not affect the gas composition.

Structure advantage

1.There is no thin oil lubrication throughout the compression system, avoiding the possibility of oil contact with high pressure and high purity nitrogen.

2. The whole system has a simple mechanical structure for easy control and easy operation.

3.For compressed gas media, there is no contamination and the nitrogen purity at the compressor inlet and outlet is the same

Nitrogen booster compressors have many applications

1. Increase the pressure of laser cutting nitrogen

Nitrogen plays a protective gas role in laser cutting, and medium-pressure nitrogen is mainly used for blowing oxygen to prevent metal cutting and surrounding oxidation at high temperatures during the cutting process, and improve the cleanliness and aesthetics of the cutting surface.

2. Nitrogen storage

Generally, the outlet pressure of the PSA nitrogen generator is less than 10barg. It is more economical if the nitrogen generator has a larger displacement, or if it is charged at night using peak and valley power. It needs to store nitrogen for later use.

English

English русский

русский Français

Français Español

Español عربى

عربى